Demand for fresh fruits and vegetables continues to rise. The contributing factors over the past few decades have been the increased purchasing power of the shopper, changing consumer perceptions, an awareness of the relationship between good eating and good health and the growing population of immigrants accustomed to fresh produce diets.

But in the supply chain, matching supply to demand is a complex mathematical art form. In fresh food, especially fresh produce, the supply varies and the demand continues to grow. Managing these variables on a day-by-day or load-by-load basis is a constant challenge. Making matters worse, supplies are often fragmented by region and season, creating the need constant re-alignment and intense oversight. Couple all this with a short shelf life making fresh food unsaleable or it simply turns to rubbish. Sitting on inventory is simply not an option.

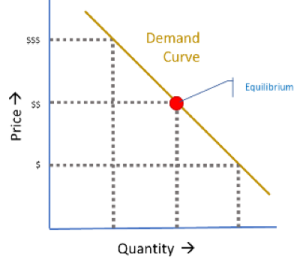

Also, price disparities can be immense. Pricing volatility is an indication of an unstable supply, married to variable demand. And as per the laws of supply and demand, this instability manifests itself in price. During my tenure at a former company, FoodLink, I could watch a multitude of price points be committed to for a single commodity. All this occurred as these prices changed moment by moment. It was not uncommon for the price to show a variation as much as 40% across all purchase orders within that same trading hour. Mostly I was watching fresh produce where I witnessed these tremendous gaps in open market pricing.

But what is really going on here? Why was there such variation? Were the lower prices set by desperate price takers? Were they merely dumping surplus product on them market? Or did the high price getters simply know the game better, have a better brand or some other market leverage? How much of a role did transportation costs play?

The lesson here is that for price to be stable, both supply and demand must also be stable. For supply and demand to be stable, inventory levels must be stable. For Inventory levels to be stable, harvesting must be stable, and for harvesting to be stable, planting and production schedules must be stable. How else can we forecast with any level of certainty?

But how do you accomplish this level of stability? Are we doomed to always be reactionary in our approach? For many in the fresh food business, especially fresh produce, being reactionary is the best that can be done. Skilled traders manage their trading desks, set pricing and manipulate harvest yields as best they can. It takes a skilled operator to understand the moving parts and navigate them successfully. Skilled operators know that relationships matter and that being in-the-know is sometimes the best asset of them all.

When you don’t control the market, and therefore can’t control supply and demand, the best you can do is to diversify. Spread yourself across many crops, many regions and many products. Allocate some volume to predictable contract pricing, but also allocate a portion to open market pricing. Harvest from different regions and manage a multitude of growers. Diversify, diversify and diversify, spread out your risk. Hope for the best, and deal with the unforeseen variables when then come. Because they surely will come.

But is there another way?

Today, we see the role technology can play but we haven’t fully realized one of its greatest assets, -big data, -deep analytics and machine learning. We’ll be covering more on this in future posts, but in short, can better forecasting and insights take out some of the pot holes on the road to profit? We think it can.

Mark Peachy, the founder and managing director of Prophet, a popular ERP solution sums it up nicely. In his white paper, The Future of Technology in Fresh Produce – An ERP Software Perspective, he expands on an essential aspects of fresh food ERP’s. Spend the time necessary to do what he calls a ‘deep implementation’. To paraphrase, one must choose software providers that allow for comprehensive database structures but also allow for easy and logical data retrieval for analysis and forecasting.

At the essence, it’s about getting a system that allows for deep data retrieval, leveraging the data in a way we can use and using it to our advantage. This is a highly competitive marketplace and data is an underutilized asset.

In Mark’s opinion, most systems on the market today fall short. It’s important that we look for these tools when shopping for any new technology or, assessing the current technology we have in place. If we don’t, we will never realize the true benefits of big data, accurate forecasting, analytics and machine learning.

An efficient supply chain is one where supply always matches with demand, and pricing is stable and predictable. In a stable environment like this, business decisions can made with a high degree of certainty. Budgets can be set and met. Food waste is reduced to a minimum. Growers get paid more. Retail stores and restaurants experience fewer stock-outs and consumers will shop with confidence from a continuum of fresh food supply.

The fresh food market will always have variability, the key will be to reduce our risk with every tool at our disposal, and not rely merely on past practices and the aging skills of the market makers.

Data is our next big tool, come with us and join the party.

Lorem ipsum dolor sit amet, consectetur adipiscing elit

These Stories on Innovation

Procurant USA LLC

475 Alberto Way - Suite 230

Los Gatos, CA 95032

1-669-221-1026

info@procurant.com