Speed and throughput define good inventory management, don’t they?

In the old days, the inventory tracking of fresh produce was easy. Count the boxes, record the totals and put the product away. Prior to the 1990’s, inventory tracking by grower-shippers was a secondary concern. The focus was more about velocity. Perishable produce must be moved fast-fast-fast.

In the old days, the inventory tracking of fresh produce was easy. Count the boxes, record the totals and put the product away. Prior to the 1990’s, inventory tracking by grower-shippers was a secondary concern. The focus was more about velocity. Perishable produce must be moved fast-fast-fast.

To put the speed of inventory into perspective, for hard goods (non-perishable items) the goal might be to ‘turn’ inventory five turns per year. But with fresh produce, normal velocity might be as fast as once per day! And at peak season, turns could be greater than five times per week! By all measures, this is INSANITY! But faster is better, faster is profit, faster is necessary. Because shelf life is so short, selling out and getting inventory quantities to zero was the goal. At that time, no one lost any sleep over it because more product would be harvested tomorrow and sales teams could always get any back-ordered or short quantities onto the next shipment.

Perishable products, especially those with a shorter shelf life, were all treated this way. Receive it, cool it and get it on a truck as fast as you can. To stop and record inventory into a computer system was simply impossible, not an option, almost laughable. In my career, I’ve set up several inventory systems. But I remember the looks of dismay when I would suggest it. The response would usually start with, “Do you have any idea what you’re saying….” Suffice it to say, my comments were often met with firm resistance.

But as the years progressed, attitudes changed. Promoting, selling and setting up inventory control systems slowly gained acceptance. For the fresh produce industry, the first companies to adopt computerized systems were those that handled crops with a longer shelf life. These crops required fewer inventory turns. Companies with crops such as apples, peaches and tomatoes were less resistant. But companies with crops having a shorter shelf life -- crops like leafy greens -- were the last to adopt computerized inventory.

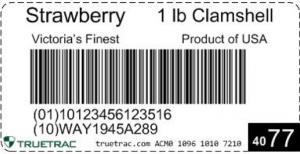

The Salinas Valley in California provides a good example of this evolution. Inventory control was simply not a ‘best practice.’ But over time, even these grower-shippers adopted an inventory mindset. Companies that grew and packed the crops with the shortest shelf life, crops like lettuce and spinach, adopted detailed inventory systems, pallet tags and, with the PTI initiative, most are labeling every case with computer generated labels today.

The Salinas Valley in California provides a good example of this evolution. Inventory control was simply not a ‘best practice.’ But over time, even these grower-shippers adopted an inventory mindset. Companies that grew and packed the crops with the shortest shelf life, crops like lettuce and spinach, adopted detailed inventory systems, pallet tags and, with the PTI initiative, most are labeling every case with computer generated labels today.

But the notion of inventory control still faces resistance in the produce industry. Inventory is still not well received across the entire supply chain. Distribution companies, food service and retail receivers are among those taking a more cautious approach. These companies are not typically growers or shippers or processors. Rather, they buy their fresh produce from the growers, shippers and processors. These receivers typically have distribution centers located around large metropolitan population centers. High volumes, diverse product lines and local delivery routes are their forte. Velocity and volume rule the day. Speed equates to profitability. The efficient business behaviors that correlate with high customer service are the performance metrics that drive business behavior. Inventory tracking takes a back seat to throughput. Sound familiar?

This is changing, though. I recently attended the United Fresh Produce show in Chicago, one of the biggest trade shows for the fresh produce industry. I listened to Michael Muzyk, the President of Baldor, as he announced with great pride that the time has come for his company to track every bit of inventory at receiving. His goal is to trace it through his entire operation, scanning every case for accurate and thorough traceability. This is no small feat as Baldor is one of the top distribution companies in North America servicing clients in New York City and the greater New England area.

Inventory processes are so important today. If your company hasn’t yet grabbed this bull by the horns, I highly recommend you get started immediately. The world is changing and you need to be ready.

In this business, inventory control is just the beginning. Inventory is not only about quantity, but it will soon be the mechanism to attach traceability information, quality control inspections, validate cold chain events and document food safety compliance. Over the next decade, I predict we will see the wholesale adoption of inventory systems for all companies in the fresh produce supply chain. Inventory tracking will be the foundation, a platform to deliver a much larger story, and much larger benefits. Each carton will carry all the information about its own travels through the supply chain. Each purchase order will deliver a 360-degree view of every shipment, every lot and every case. Scan a barcode with your smart phone and the full provenance of that item will be there for you to see.

This industry is poised to achieve the next level. The purchase order, the lot, the load, pallet and carton will be connected to everything about the entire supply chain transaction. Secure data will deliver transparency across a blockchain-enabled ‘smart’ data structure and inventory systems will be the backbone from which will hang all aspects of the transaction.

This is the change that is coming, and it is the future that drives our thinking here at Procurant. Is your company ready?

Lorem ipsum dolor sit amet, consectetur adipiscing elit

These Stories on Events

Procurant USA LLC

475 Alberto Way - Suite 230

Los Gatos, CA 95032

1-669-221-1026

info@procurant.com