It goes without saying that consumers of fresh produce expect their food to be safe to eat and that it be of the highest quality. They hold retailers or food service organizations responsible for this. One bad experience can severely impact future buying decisions and inflict lasting damage on a brand.

Fair or not fair, this is reality. Consumer experience and perception can lift or sink a brand, and it underscores the importance for those in the business of fresh food to hold their supply chain accountable for maintaining processes and procedures that uphold food safety and food quality.

Fair or not fair, this is reality. Consumer experience and perception can lift or sink a brand, and it underscores the importance for those in the business of fresh food to hold their supply chain accountable for maintaining processes and procedures that uphold food safety and food quality.

We all know that the food supply chain is very complex. There is an intricate dance to get fresh produce from the farm to the consumer’s table. Each organization has a responsibility to practice and enforce procedures and to follow processes to protect food from exposure to potential hazards. The big question is how many are really following through with daily food safety processes and procedures?

It requires vigilance to understand and enforce quality and safety measures across your supply chain. Certificates and audit results alone may be sufficient. The CDC estimates that each year roughly 1 in 6 Americans (or 48 million people) gets sick from foodborne pathogens every year. In 2020 there were hundreds of outbreak cases in the United States, and major fresh produce recalls in big categories such as romaine lettuce and onions. These types of recalls cost time and resources to address, and they inflict enduring damage on brands and categories.

It requires vigilance to understand and enforce quality and safety measures across your supply chain. Certificates and audit results alone may be sufficient. The CDC estimates that each year roughly 1 in 6 Americans (or 48 million people) gets sick from foodborne pathogens every year. In 2020 there were hundreds of outbreak cases in the United States, and major fresh produce recalls in big categories such as romaine lettuce and onions. These types of recalls cost time and resources to address, and they inflict enduring damage on brands and categories.

What if a retailer or food service organization had visibility into daily, weekly or monthly activities across its supply chain to ensure that compliance and food safety programs were being followed? What if there was some way to have “peace of mind” that processes and procedures are routinely followed to help reduce chances of contamination or outbreak?

Digital recordkeeping — the computerized tracking and storing of information in easily accessed and reportable systems — offers just such a possibility. It is one of the reasons why many organizations across the food supply chain are beginning to use mobile, cloud-based systems from the field to the grocery aisle.

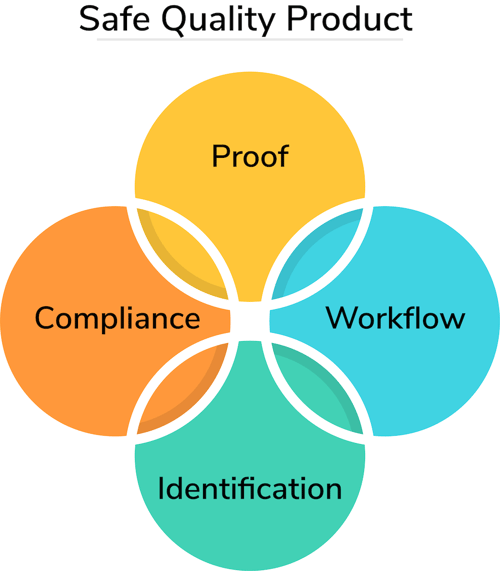

There are a bewildering variety of approaches to digitizing a supply chain, but for the food industry a comprehensive solution must offer key components that address:

Compliance with all required procedures in any business is easier said than done. In the food industry, safety and quality go hand in hand with adherence to regulatory, certification, licensing and audit processes. But this is a challenge for most day-to-day operational environments where urgent issues constantly arise and pressure to deliver product is relentless. Complying with food safety and quality procedures requires preparation and training, both of which can be overwhelming and taxing on front line staff.

Mobile, digital tools have been proven to reduce the time and effort required for food safety activities. Rather than having staff step out of their daily routine to fill out forms or write down information in bulky binders, digital task management works within the flow and context of daily activities. Compliance is much easier to achieve, and training time significantly reduced. The information is also readily available and quickly retrievable, allowing for faster problem identification and mitigation.

There are numerous procedures and processes that must be carried out to keep food safe as it journeys through the supply chain.

Digital task management automates these standard procedures and processes while bringing new visibility to staff compliance and helping quickly spot potential problems. Such a system typically notifies management when there is a variation in the flow of activity. For example, if food is not being kept at an appropriate temperature, an alert rapidly triggers corrective actions. This capability for automation and timely intervention reduces the risk of food being compromised, reduces costs and cuts down dramatically on waste.

Digital task management automates these standard procedures and processes while bringing new visibility to staff compliance and helping quickly spot potential problems. Such a system typically notifies management when there is a variation in the flow of activity. For example, if food is not being kept at an appropriate temperature, an alert rapidly triggers corrective actions. This capability for automation and timely intervention reduces the risk of food being compromised, reduces costs and cuts down dramatically on waste.

All food items — especially fresh produce — must be identified throughout the journey from producer to end consumer. Most food producers and shippers use labels with barcodes that can be scanned or read quickly by machines to track and manage inventory. Those labels have become more sophisticated with industry efforts such as the Produce Traceability Initiative (PTI) encouraging and supporting the difficult task of tracking fresh produce from the field to individual retail locations.

A digital food integrity and protection solution must also begin in the field, and it makes sense to merge PTI and food safety efforts by having the joint system include the ability to print a PTI label immediately at harvest. That information then follows the food as it passes through the supply chain with a “digital footprint.”

As the fresh food moves through the supply chain, proof of compliance and adherence to required process is essential. Every business in the supply chain must have the capability to quickly provide documentation such as certifications, licenses, audit results and food safety plans. Today, these documents are often kept in binders or scanned and emailed as needed

A comprehensive digital solution would include the capability to house, store and share appropriate documentation with partners instantly upon request. This kind of document repository should be included in the solution, allowing for the consolidation of critical documentation and the ability to share any kind of media — certifications, inspection reports, compliance logs, photos and videos — easily and quickly with multiple partners.

There should never be compromises when it comes to food safety and quality. There are already enough risks to fresh produce it moves through the supply chain. Preventable risks such as inattention to process or poor compliance with safety procedures can be addressed with the capabilities of today’s mobile, cloud-based technology.

It might seem that a comprehensive, digital food safety solution across the supply chain is an overly-ambitious goal. But technology today is far more affordable and easily deployed than in years past. For example, consider the ubiquitous smart phones in use everywhere. The same infrastructure that powers those devices can be harnessed to ensure safe, fresh food moves efficiently through your supply chain.

It might seem that a comprehensive, digital food safety solution across the supply chain is an overly-ambitious goal. But technology today is far more affordable and easily deployed than in years past. For example, consider the ubiquitous smart phones in use everywhere. The same infrastructure that powers those devices can be harnessed to ensure safe, fresh food moves efficiently through your supply chain.

Every business in the food supply chain needs a good technology partner. The days of keeping records in three-ring binders is past, and the opportunity to cut costs, reduce risks and increase compliance with food safety policies and procedures offers a compelling reason to consider digitizing aspects of the foods supply chain.

Everyone from growers and shippers to retailers and food service organizations has a stake in modernizing and improving this important industry. Consumers will always remain at the top of this industry’s food chain. For retailers and their partners across the supply chain, digitizing food safety promises those consumers a future of safe, high quality food.

Cloud-based solutions that digitize task management and enable fast, efficient sharing of information ensure that those consumers enjoy your products for years to come while bringing new levels of visibility, compliance and trust that everyone is doing their part to ensure that food is safe and of the highest quality.

Cloud-based solutions that digitize task management and enable fast, efficient sharing of information ensure that those consumers enjoy your products for years to come while bringing new levels of visibility, compliance and trust that everyone is doing their part to ensure that food is safe and of the highest quality.

It doesn’t get much better than that.

These Stories on Food Safety

Procurant USA LLC

475 Alberto Way - Suite 230

Los Gatos, CA 95032

1-669-221-1026

info@procurant.com